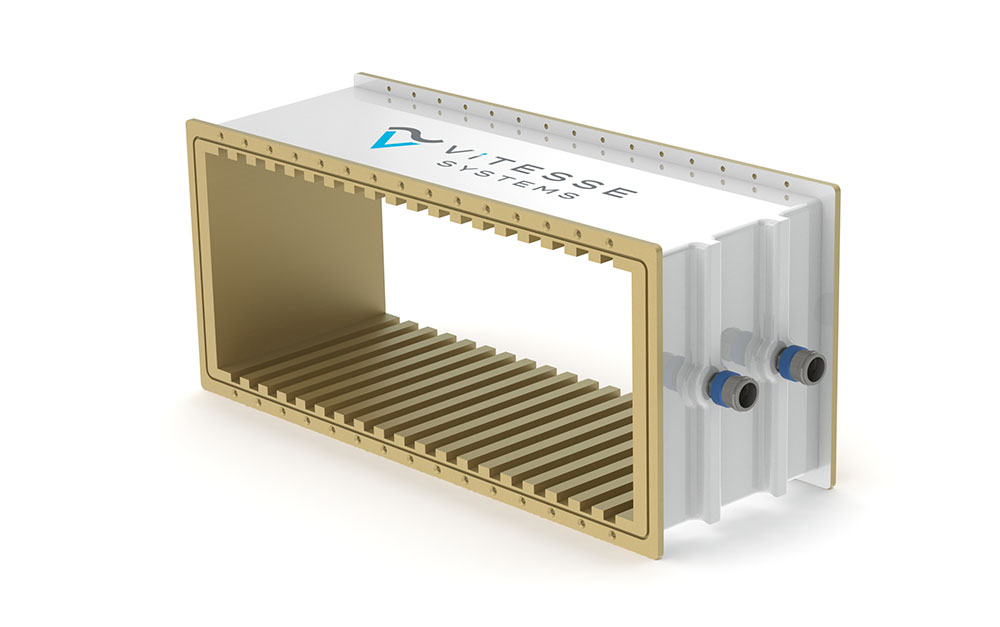

Liquid cooled chassis assemblies are an assembly of one or more liquid cold plates to provide an electronics enclosure with integrated cold walls. The integrated cold wall structure provides direct cooling to the electronics within the structural enclosure. Like liquid cold plates, liquid cooled chassis assemblies are a way to transfer heat effectively and efficiently from high powered electronics boards to a cooling liquid that flows though the walls of the enclosure and transports it to another location to be dissipated. Liquid cooled chassis provide a more integrated solution vs. liquid cold plates in applications where there are multiple electronics boards that need to be cooled.

Liquid Cooled Chassis Assemblies

Liquid Cooled Chassis Manufacturing

Liquid cooled chassis can be manufactured using vacuum brazing or dip brazing technologies at Vitesse Systems.

Vacuum Brazed Liquid Cooled Chassis

Like liquid cold plates, the chassis can be manufactured using vacuum brazing. Vitesse Systems Newark was founded on a long history of vacuum brazing and provides the highest quality brazed products in the industry. In vacuum brazed liquid cooled chassis, each cold wall (cold plate) is broken down into pre-brazed components per Vitesse standards to ensure the best brazing configuration. After brazing, Vitesse machines the cold plate to a final or semi-final condition to prepare it for chassis assembly. Once ready for assembly, our experienced assembly team constructs the chassis, component by component, ensuring a consistent end product. Some liquid cooled chassis applications have tight tolerance features that need to be machined after assembly, at this point the entire chassis will be loaded into a CNC mill and machined to its final condition.

Dip Brazed Liquid Cooled Chassis

Liquid cooled chassis can also be manufactured using the Dip Brazing process. Vitesse Systems Clinton was founded on a long history of dip brazing and provides the most complex dip brazed products in the industry. In dip brazed liquid cooled chassis, the enclosure is broken down into pre-brazed components per Vitesse standards to ensure the best brazing configuration using proprietary fixturing techniques. After brazing, Vitesse machines the brazed chassis assembly to its final condition. What set’s a liquid cooled dip brazed chassis apart from its convection cooled counterpart, is a brazed tube assembly along the outer walls of the chassis where the liquid is channeled to provide the cold wall cooling function in a dip brazed assembly.

Request a Quote

Quality in complex engineered solutions

All Vitesse Systems locations are AS9100:2016 certified and provide the highest quality design and manufactured solutions.