Vitesse Systems can meet your additive manufacturing requirements with our SLM280 and SLM500 metal 3D printers.

Additive Manufacturing Capabilities

Thanks to our 20+ years of manufacturing and design experience and our growing AM knowledge base, we can quickly turn your designs or requirements into a 3D-printable part — saving you time and mass while lowering the number of parts in a design.

We Meet You Where You Are.

From the beginnings of an idea and some specifications to a completely DfAM optimized, ready to 3D print design, and everything in between — Vitesse Systems can help you realize your part needs via additive manufacturing.

Our RF, Mechanical, and Additive Manufacturing engineering teams can help you understand the applicability of metal 3D printing to your requirements. They can also help you to understand when one of our more traditional methodologies is better suited to your needs.

Printers and Powders

SLM280 (build volume of 11″ x 11″ x 14″)

SLM500 (build volume of 19”x11”x14”)

Powders: AlSi10Mg and A6061-RAM2

We are open to exploring other powders at your request.

Post-Processing Capabilities

Vitesse Systems has the machining resources required for removing parts from the bases and supports that are necessary during the additive manufacturing process. We have the ability to electroplate gold, silver, nickel, and copper in-house. We also have the capability to heat treat parts based on your requirements or ours. We are continually developing new methodologies for improving surface roughness.

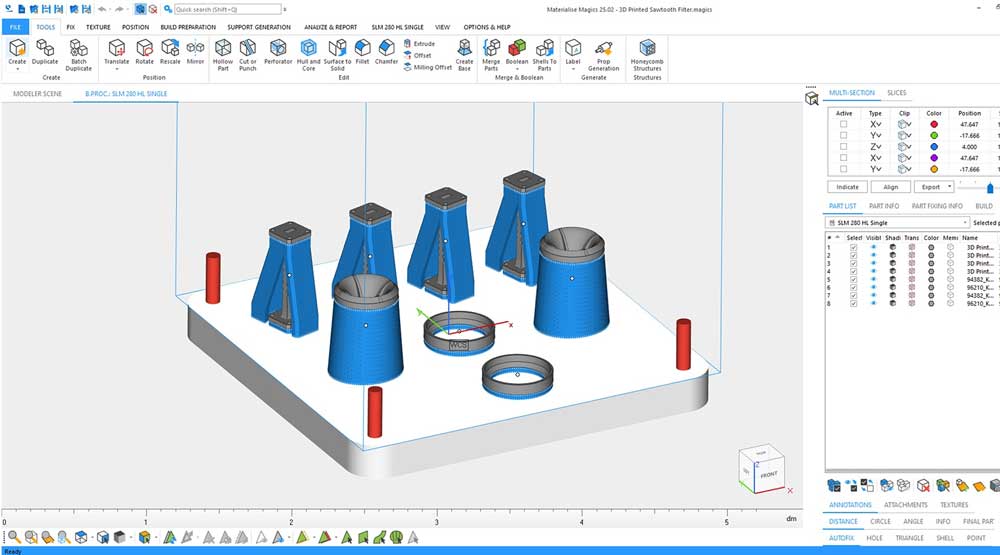

DFAM

Vitesse Systems uses Materialise Magics software to aid in determining the printability of designs. Our engineering teams are rapidly expanding our understanding of designing printable parts while maintaining critical RF, thermal, or mechanical performance.

AM Experience

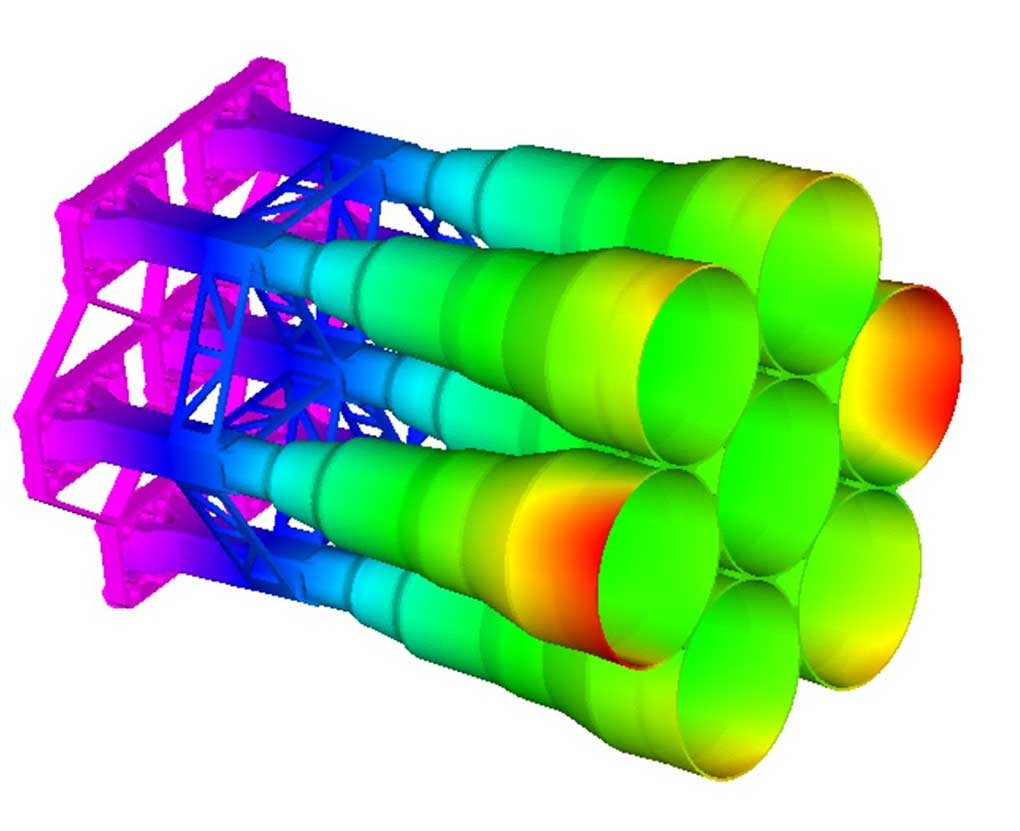

We have printed and successfully tested a variety of our existing parts including horns, OMTs, and feed array networks. Our team has improved these builds to reduce the mass and number of parts required by taking advantage of the design constraints removed by additive manufacturing.

Due to this experience, we are confident in our ability to print parts that will consistently meet industry mechanical and RF specifications.

Additive Manufacturing Process Qualification

We are currently qualifying our AM machines and processes with multiple aerospace customers. We are developing an internal qualification standard based on NASA-STD-6030 as a guideline. Reach out today to discuss your qualification requirements.