Uniting Design, Build, and Test

The systems of next aren’t enabled by ideas alone. They require a partner that can do more than just ideate ambitiously, but deliver materially. At Vitesse we make aspirational technology into a tangible reality with comprehensive in-house design, manufacturing, and testing capabilities to create what others can’t at the speed your mission needs.

What Drives the Vitesse Difference?

Solutions Delivered Sooner

Achieve faster development and turnaround times with proven internal coordination methodologies and a simplified vendor supply chain.

Remediate Risk and Ensure Project Success

Reduce the risk of costly production and project errors with consistent quality assurance standards and open lines of communication with Vitesse team members.

Collaboration Across Locations

Our professional project management organization helps coordinate internal teams across Vitesse locations while maintaining open lines of communication with external client teams.

Placing an Emphasis on Partnership

We provide our clients with a single point of contact throughout the entire process to simplify project oversight and ensure seamless coordination with any Vitesse location.

Scalable Production Capacity

From small batch to production calls, we have the capacity to handle any size program and use our extensive volume production expertise to deliver repeatable, high-quality, high-volume processes for consistent product delivery.

Optimized Designs for Optimized Performance

From technical specification development through design optimization and validation, our extensive heritage across RF, thermal, and mechanical engineering enables us to ensure every solution provides peak performance.

Producing the Impossible

Making the new possible, achievable requires the ability to create what others can’t. At Vitesse, we bring to bear a set of manufacturing capabilities that’s second to none in our industry, leveraging each one in unison to deliver integrated solutions that enable unprecedented performance.

Core Manufacturing Capabilities

Additive Manufacturing

Allows us to create complex, fully customizable internal geometries to suit specific solution applications like directing liquid or antenna signals.

Precision CNC Milling

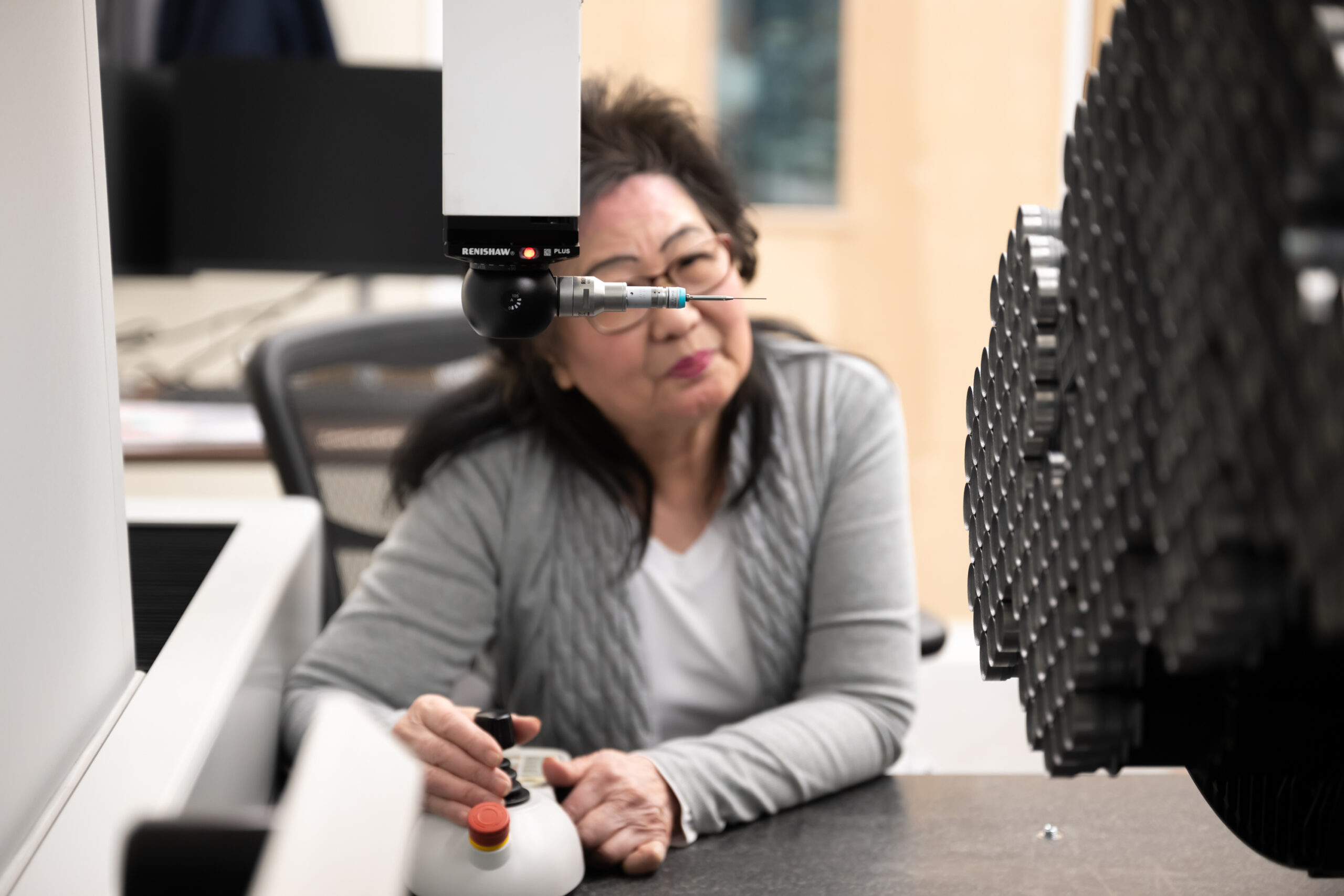

Forms the critical surfaces of the fluid channel, waveguide, or radiating surface within solution systems.

Metal Finishing

Our engineering experts are able to control metal finishing operations in-house from precious metal plating to coating, reducing project risk and lead times.

Mechanical & Electrical Assembly

We create fully-integrated subassemblies within our core solution areas by mechanically assembling components, installing hardware, and integrating active RF components or circuit card assemblies.

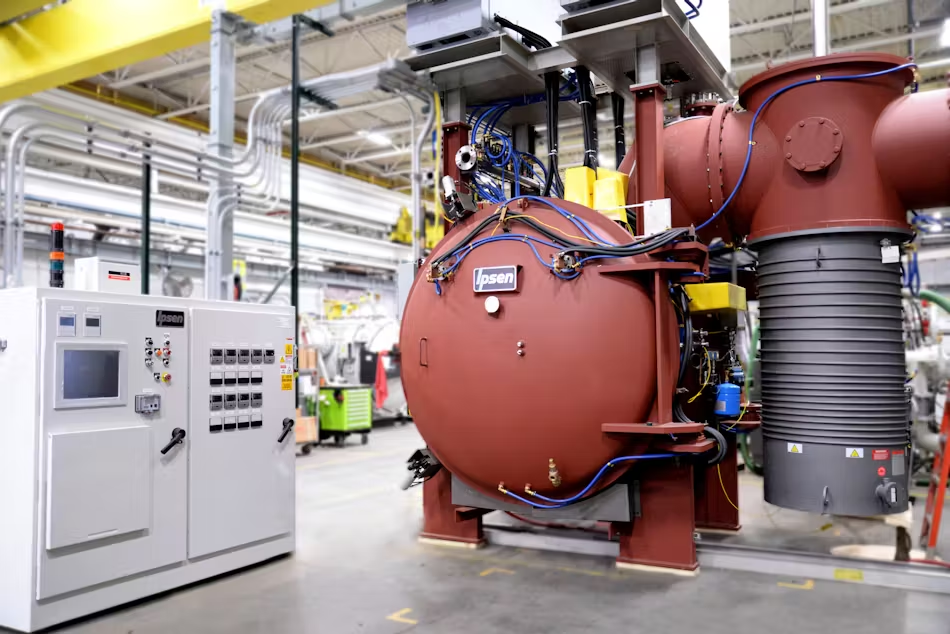

Metal Joining Expertise

Our expansive production toolkit includes deep expertise in vacuum brazing, dip brazing, and certified welding, which we utilize to create clean internal channel geometry within our integrated systems. By ensuring clean and consistent internals within all our solutions, we optimize system performance and reliability.

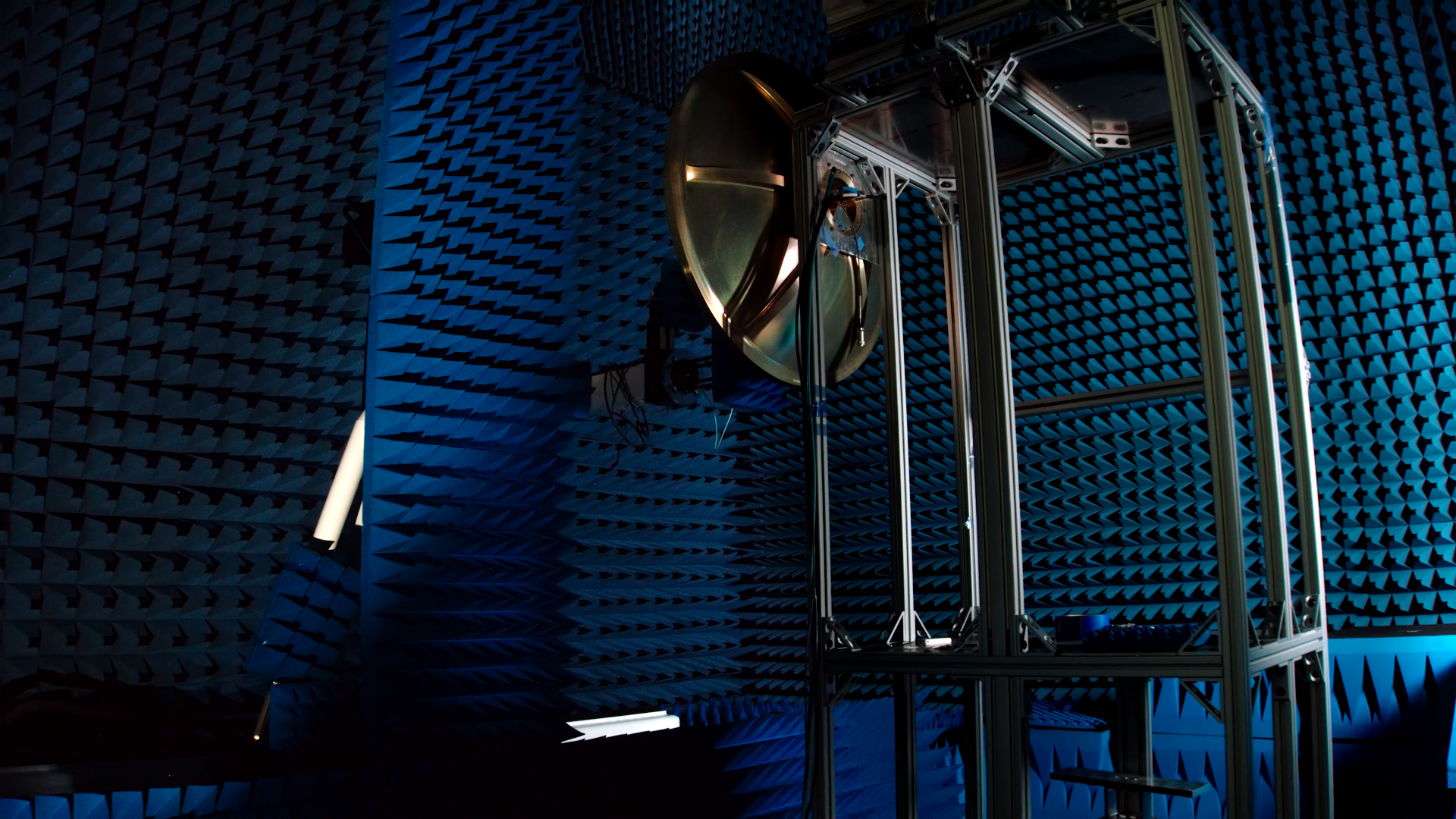

In-House Validation and Testing

Our wide range of in-house product acceptance and qualification testing extends across everything from thermal management to RF performance and environmental testing. By bringing these testing capabilities in-house, we eliminate the inefficiencies of multi-vendor supply chains and enable our engineering teams to rapidly iterate and improve on design concepts using actionable insights.

Ready to get started?

Get in touch with our team of engineering experts and find the right solution for your mission.