Performance, Enabled

The modern battlefield requires modern solutions. Our advanced thermal management enable critical next-generation capabilities.

What Are Liquid Cold Plates?

Liquid cold plates are thermal components that remove heat from electronics by transferring it directly into a circulating liquid coolant. By using liquid instead of air, they deliver higher heat removal in compact, high-power designs used across defense, space, telecom, and computing systems.

How Liquid Cold Plates Work

Heat conducts from electronic components into the cold plate, where internal flow channels route coolant through high-heat areas. The fluid absorbs and carries heat to a heat exchanger, enabling precise temperature control in high-density electronic assemblies.

Engineering & Design Advantages

Liquid cold plates outperform air cooling for high-power electronics by reducing thermal resistance, supporting higher power density, and improving reliability. Custom designs optimize flow paths, materials, and interfaces to meet demanding thermal and mechanical requirements.

Vitesse Systems Liquid Cold Plate Capabilities

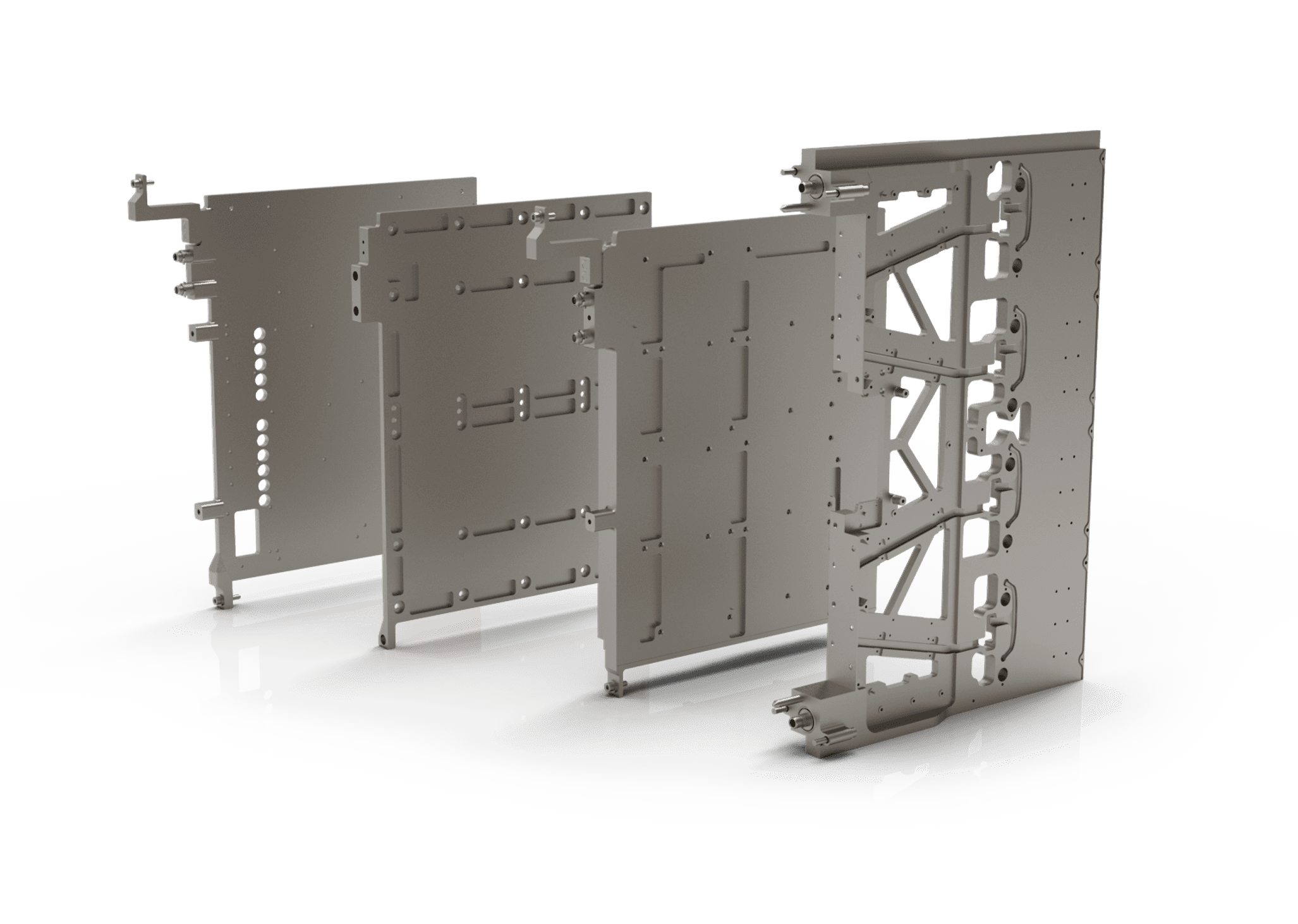

Vitesse Systems designs and manufactures fully custom liquid cold plates built to meet exact application and production requirements.

Vacuum-Brazed Construction

Our vacuum-brazed manufacturing process produces strong, hermetically sealed cold plates with excellent structural integrity and long-term leak resistance. Designs range from single-board cold plates to complex, multi-function assemblies, including integrated RF structures and thermal components.

Material Options

We support a wide range of materials to balance thermal performance, weight, and environmental durability, including:

- Aluminum

- Copper

- Stainless steel

- Copper-nickel (CuNi) alloys

Additional materials can be evaluated based on application needs.

Precision Machining & Integration

From early prototypes to full-rate production, we maintain tight dimensional control, high surface flatness, and consistent quality. Manufacturing and inspection processes are aligned with AS9100 requirements to support mission-critical programs.

Applications

Liquid cold plates are used across a broad range of high-performance applications, including:

- Defense and space electronics

- High-performance computing and data centers

- Power electronics and semiconductor systems

- RF, radar, and telecommunications hardware

- Electric vehicle and energy storage systems

In each case, effective thermal management enables higher performance, greater reliability, and more compact system designs.

Ready to get started?

Get in touch with our team of engineering experts and find the right thermal management solution for your mission.